Tech Radar

EV vary anxiousness may very well be a factor of the previous because of Mercedes’ new photo voltaic paint – which guarantees 1000’s of free miles a yr

- Mercedes has unveiled a sequence of future improvements throughout workshops

- Its ‘photo voltaic paint’ accommodates no uncommon earths and no poisonous supplies

- Aerodynamic braking and energy converters goal to enhance EV efficiencies

What’s photo voltaic paint?

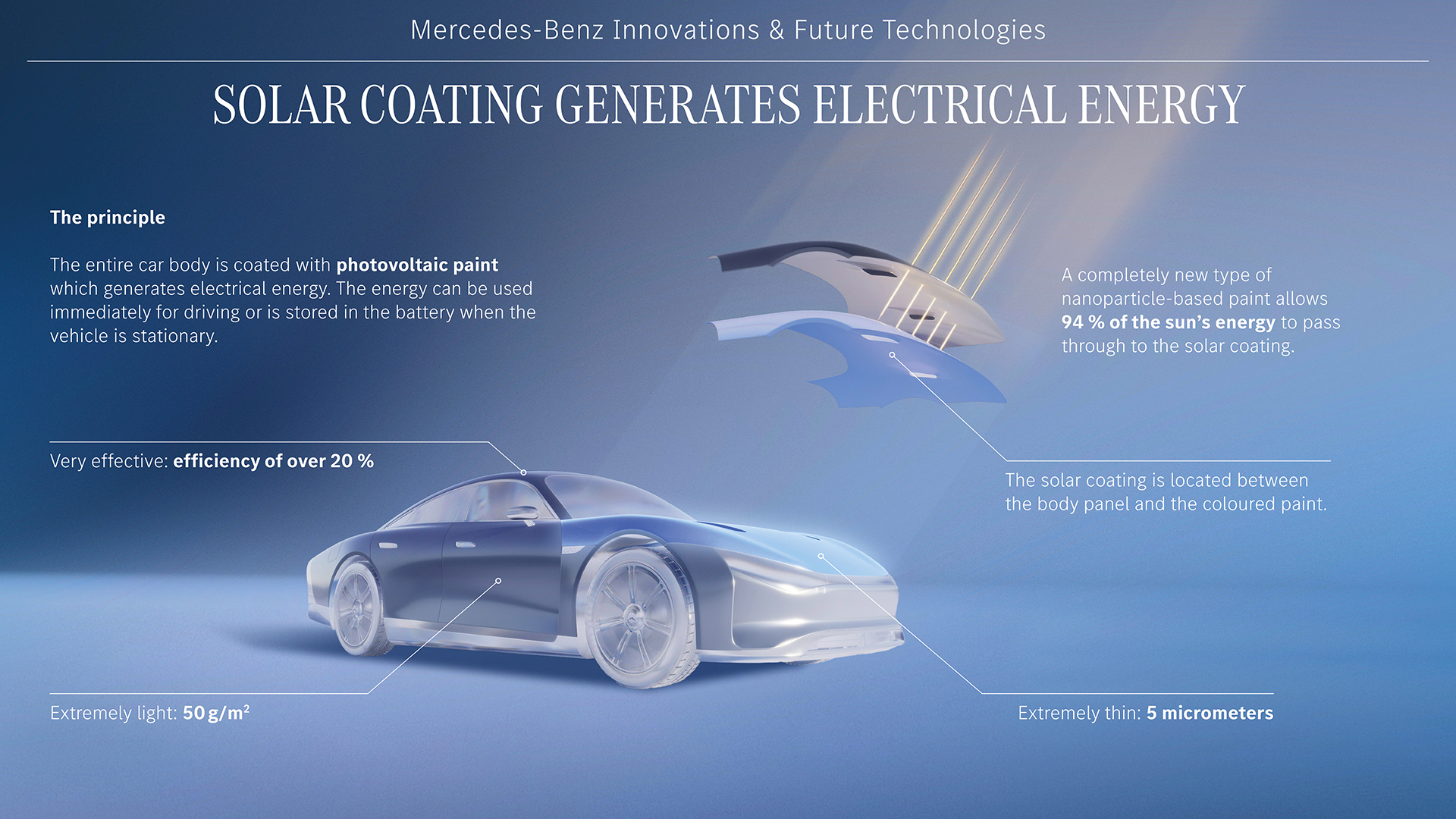

Mercedes says it is new form of photo voltaic paint can be utilized on “all exterior automobile surfaces”. It additionally claims it is “significantly cheaper” to provide to typical photo voltaic modules and is straightforward to recycle, because of the dearth of uncommon earth supplies and silicon.

The utopian dream of solar-powered motoring won’t be so distant, as Mercedes-Benz just lately opened the doorways to a few of its most forward-thinking engineering laboratories – and it seems photovoltaic surfaces are very a lot on the agenda.

Throughout numerous workshops in its home metropolis of Stuttgart, Germany, Mercedes-Benz lifted the lid on the way it has been engaged on a brand new form of photo voltaic floor that would generate sufficient electrical energy for folk in sunnier climates to cowl their each day commuting necessities.

In accordance with the German marque, the ‘photo voltaic modules’ measure simply 5 micrometers in thickness – considerably thinner than a human hair – and weigh simply 50 grams per sq. meter. They are often utilized to nearly any substrate, with purposes of future vehicles possible coming within the type of a “wafer-thin layer of paste” that may cowl a lot of the physique work.

Mercedes-Benz has previous expertise with photo voltaic panels and the impression they will have on the electrical vary of EVs, as the corporate’s record-breaking EQXX concept (the rolling lab that drove greater than 620 miles on a single cost) used a small photo voltaic panel on the roof that added round 30km (18 miles) of extra vary throughout one in all its lengthy distance report makes an attempt.

However the breakthrough in photovoltaic floor remedies means rather more of a automobile may very well be coated, equating to a a lot larger improve in extra EV mileage.

No large photo voltaic panels wanted

Taking a reasonably commonplace mid-sized SUV just like the marque’s EQS for example, Mercedes engineers declare the 11 sq. meter floor space and the 20% photo voltaic efficiencies of the know-how could be sufficient to generate round 7,400-miles of motoring per yr in someplace sunny, like Los Angeles.

Nanoparticle-based paint would additionally enable 94% of the solar’s power to go via to the photo voltaic coating, which means future EVs will not essentially need to appear like large photo voltaic panels.

Learning the each day driving habits of EV homeowners in Stuttgart, Germany, these near the undertaking discovered they cowl a mean of 52 kilometers (round 32 miles) a day. Round 62% of this distance could be coated utilizing photo voltaic power, the corporate says, regardless of the customarily poor climate situations.

Once more, when you stay someplace with loads of extra sunshine, the ‘always-on’ nature of a photovoltaic floor means the automobile may successfully be charging, even when parked.

Because of this, LA homeowners may cowl 100% of their driving distance on common by photo voltaic power. Any surplus achieved may very well be fed straight into the house community by way of bidirectional charging, in principle.

Braking down inefficiencies

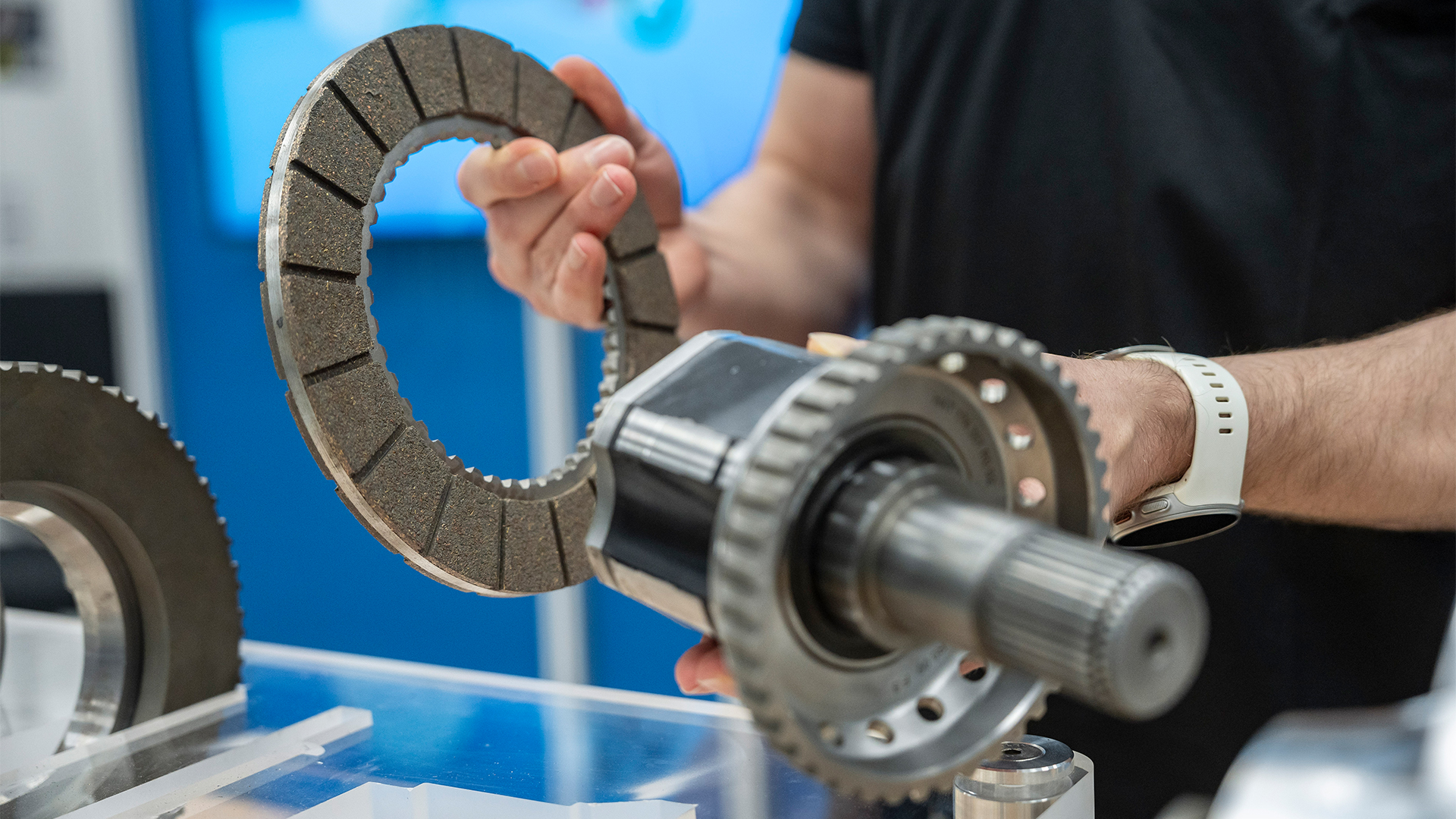

Alongside pondering the state of future cities and rushing up AI choices with neuromorphic computing, Mercedes-Benz additionally touched on the truth that additionally it is engaged on an EV braking system that removes the necessity for traditional discs, drums and pads.

Successfully ridding the world of dangerous particles emitted within the type of brake mud, Mercedes’ innovation is built-in into the electrical drive unit on the entrance or rear axle, negating the necessity for in-wheel brakes.

Not solely would this be topic to minimal put on and take up much less house, it could additionally imply the corporate may take a look at a lot lighter wheel and tyre mixtures, lowering the general mass of an EV, in addition to exploring fully-enclosed rims for optimized aerodynamics, as openings for brake cooling would not be required.

Plus, the corporate’s analysis into electrical inverter methods may see the mixing of micro-converters straight at battery-cell degree, which might enable for larger control over particular person cells.

It’s sophisticated stuff, however it could lead to extra environment friendly battery efficiency, elevated the longevity of battery pack lifespans and larger freedom in the case of packaging – permitting engineers to make use of various cell designs all through the automobile.

All of those developments are nonetheless a great distance from making manufacturing, however it’s good to see Mercedes-Benz busy exploring improvements that supply its future prospects real-world worth.

You may additionally like

Source link